- Sustainability

- Contact Us

- PR Center

- EN

-

HYOSUNG ADVANCED MATERIALS LOGO

R&D

through constant challenge and innovation

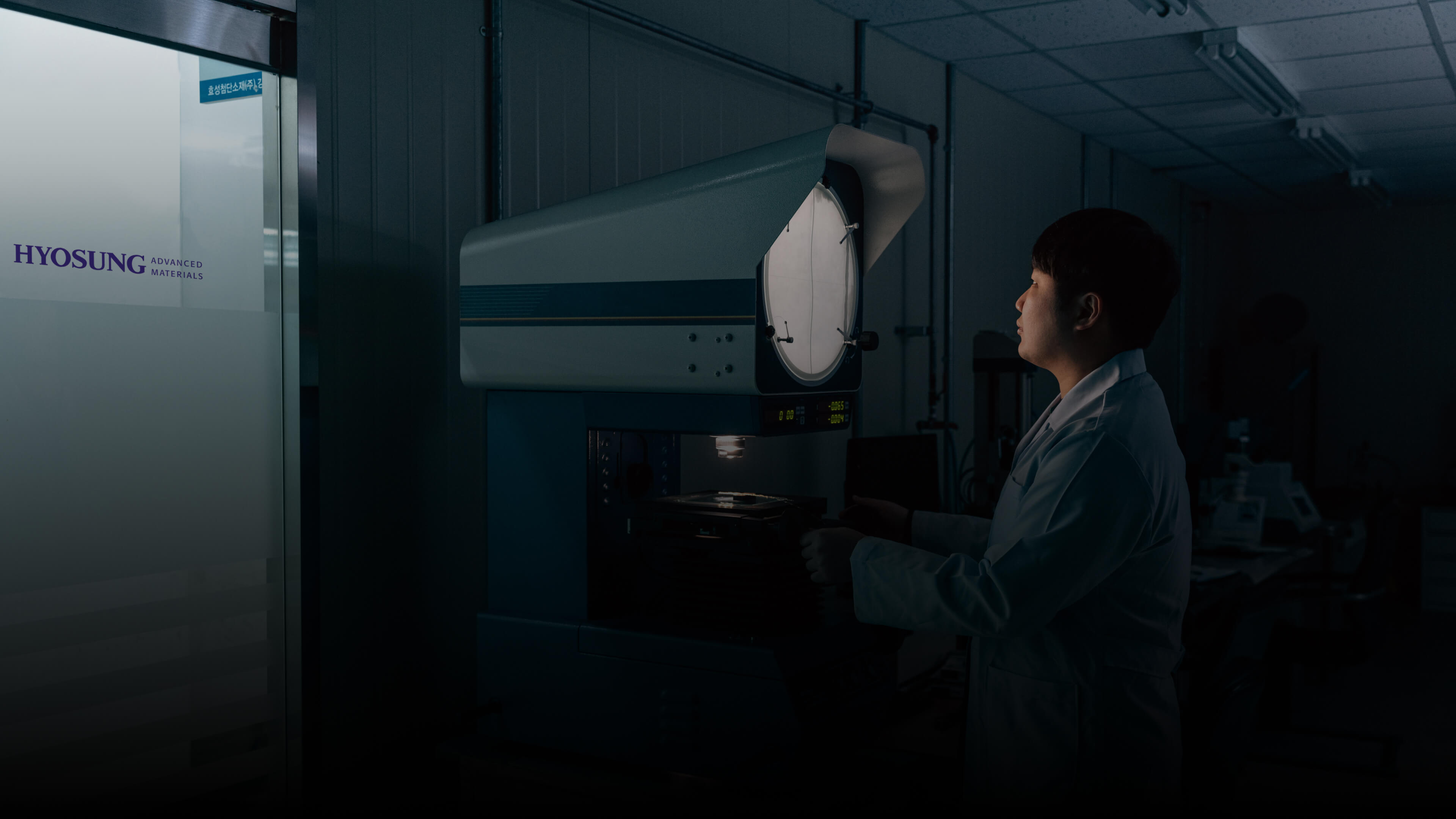

Hyosung Advanced Materials has been conducting research in the fields of fibers, steel cords, and composite materials, building upon the research capabilities of Hyosung R&DB Labs, the first private research institute established in Korea in 1971, and Steel Wire Technical

Center, founded in 1986 to focus on steel technology.

Our goal is to develop safer and more comfortable products for humanity and provide optimized solutions to our customers by continuing our research in these areas.

through constant challenge and innovation

Hyosung Advanced Materials has been conducting research in the fields of fibers, steel cords, and composite materials, building upon the research capabilities of Hyosung R&DB Labs, the first private research institute established in Korea in 1971, and Steel Wire Technical

Center, founded in 1986 to focus on steel technology.

Our goal is to develop safer and more comfortable products for humanity and provide optimized solutions to our customers by continuing our research in these areas.

Based on our extensive research experience, Hyosung Advanced Materials is conducting research to improve the processes and quality of commercialized fibers such as tire reinforcement fibers, technical yarn, carpet yarn, aramid, and carbon fibers. As a leading company in the industrial fiber industry, from aramid fibers commercialized with our own technology to the first domestically-developed and commercialized carbon fibers, we are striving to develop new products and processes that our customers desire for sustainable business operations.

-

Fibers for Tire

Reinforcement -

Technical

Yarn -

Yarns for

Carpets -

Aramid

Yarn -

Carbon Fiber

&

composite

materials

Achievements in

the Field of Fiber

Research

Research Field

Steel Wire Technical Center, established for the development of production technology and products related to steel cords and bead wires using wire rods, key materials for tire reinforcement, is enhancing its research capabilities as a leading research institution for steel materials in Vietnam, China, and Korea. Hyosung's Steel Wire Technical Center is growing as a specialized research institution for steel materials, focused on eco-friendly and next-generation tire reinforcement materials, ultra-fine wires, wires for wafer slicing, and special steel cord materials development.

-

Development of

steel wire

processing

technology- Steel material heat treatment technology

- Plating and surface treatment technology

- Design and optimization of wet drawing process conditions

- Optimized wire drawing process design

- Wire joining mechanism

-

Specialized

research

on tires- Eco-friendly tire reinforcement materials

- Next-generation tire characteristic research

- Proprietary specification

-

Research on

application

field of steel wire- Wafer cutting wire Ultra-fine wire Special material wire

Achievements in

the Steel Wire

Research Field

The Carbon Materials Research Team is developing high-elasticity and ultra-high-strength carbon fibers as differentiated new products for sustainable business growth.

The team is also researching the development of radiation curing agents and heat-resistant sizing agents to improve the properties and quality of carbon fibers.

Carbon Materials Research Field

The Aramid Research Team has developed high-elongation and high-strength yarns as new products to expand the aramid product portfolio. They are also researching process improvements and heat resistance enhancements for high-strength and tirecord yarns to secure cost and quality competitiveness.