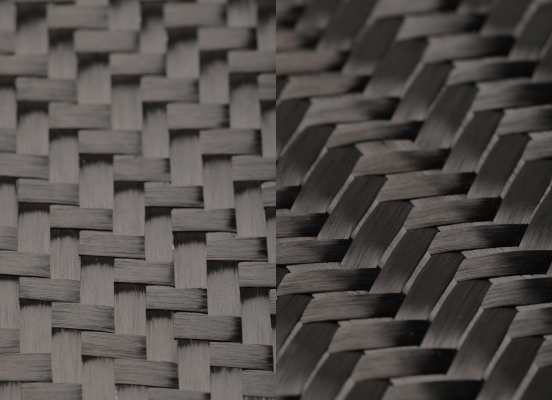

carbon fiber

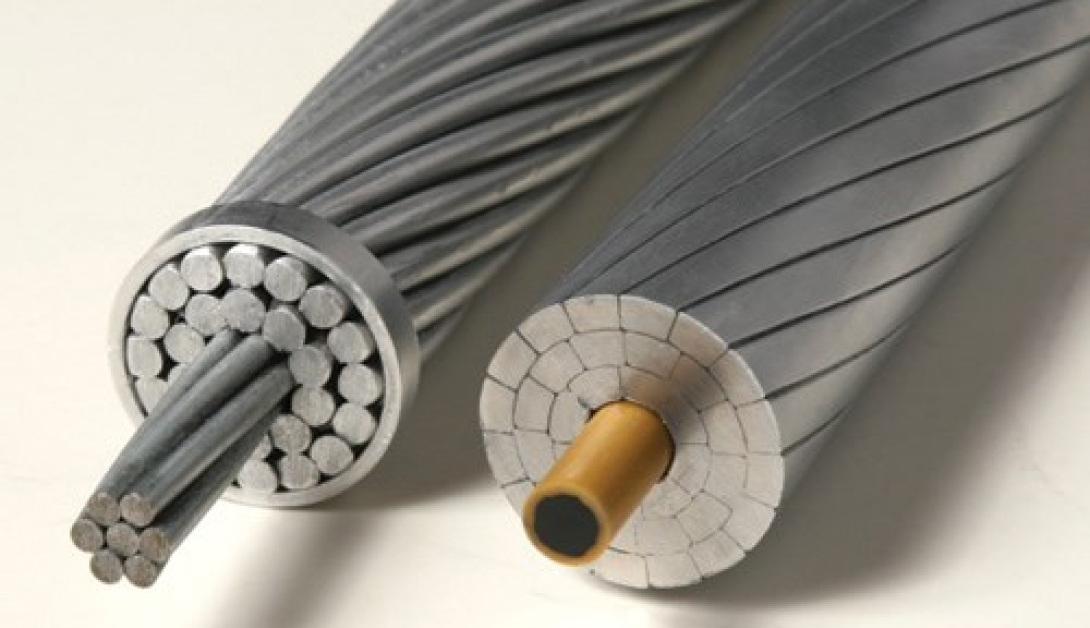

Standard modulus carbon fiber is an ultra-tensile product with excellent manufacturing characteristics for fabric, prepreg, and filament winding processes. It is an all-purpose carbon fiber used in various areas including high-pressure vessels, cable cores, general

industries, and civil engineering and construction.

Standard modulus carbon fiber is available in 6K, 12K, and 24K filaments.